FREE Oil Tank Installation Quote: 631-881-4772

We install new tanks at discounted prices! Call today to speak to one of our tank install specialists.

POPULAR TANK OPTIONS

STANDARD STEEL OIL TANK

ECOGUARD DOUBLE BOTTOM TANK

ROTH TANK

There are many options available to install an oil tank on Long Island, NY. Whether you are replacing an old tank or installing a new one, it is important to understand the various types of oil tanks available, the installation process, and the associated costs. With proper installation, an oil tank can provide reliable and efficient heating for your home or business. Contact us for a free quote on Oil Tank Installation Long Island.

There are different types of oil tanks available, including above-ground and underground tanks. Above-ground tanks are easier to install and maintain, while underground tanks offer better protection against the elements. The size and type of tank you choose will depend on your heating needs, the available space, and local regulations. It is important to work with a professional installer who can help you choose the right tank and ensure that it is installed correctly.

The installation process involves several steps, including preparing the site, removing the old tank (if necessary), installing the new tank, and connecting it to the heating system. It is important to follow local regulations and obtain any necessary permits before beginning the installation. Regular maintenance and safety checks are also important to ensure that the tank continues to function properly and safely.

Key Takeaways

- Oil tank installation involves choosing the right type and size of tank, obtaining necessary permits, and working with a professional installer.

- Proper installation and maintenance are essential for ensuring reliable and safe heating.

- Local regulations and safety guidelines must be followed throughout the installation and maintenance process.

Types of Oil Tanks

Oil tanks come in different types and sizes, and it is important to choose the right one for your home. Here are the two main types of oil tanks:

Indoor Oil Tanks

Indoor oil tanks are typically located in a basement, utility room, or garage. They are usually made of steel or plastic and come in different sizes. Indoor oil tanks are a good option if you have limited outdoor space or live in an area with harsh weather conditions. They are also easier to maintain and protect from environmental damage.

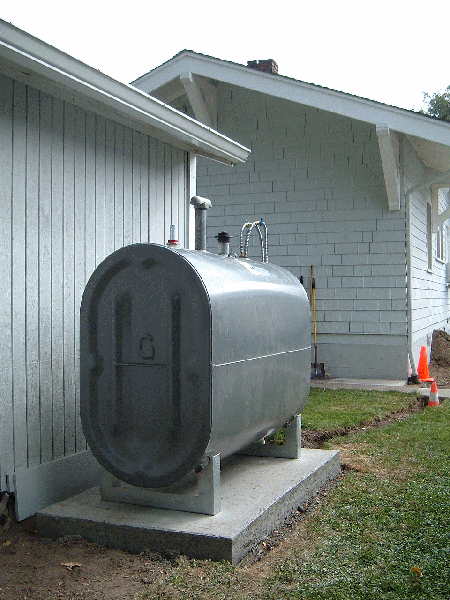

Outdoor Oil Tanks

Outdoor oil tanks are installed outside the home and are available in different shapes and sizes. They are typically made of steel and have a double-walled construction to prevent leaks. Outdoor oil tanks are a good option if you have limited indoor space or prefer not to have a tank inside your home. They are also easier to install and refill. Contact us for a free quote on Oil Tank Installation Long Island.

When choosing an oil tank, consider the following factors:

- Size: The size of the oil tank should be based on your heating needs and available space.

- Material: Oil tanks can be made of steel or plastic. Steel tanks are more durable and can last for decades, but they are more expensive. Plastic tanks are more affordable but have a shorter lifespan.

- Location: Consider where the oil tank will be installed and whether it will be exposed to harsh weather conditions.

- Installation: Oil tank installation should be done by a licensed professional to ensure safety and compliance with local regulations.

Choosing the right oil tank for your home is an important decision that should be made carefully. Consider your heating needs, available space, and budget when selecting an oil tank. We can help you choose the right tank for your home.

Oil Tank Sizes and Types

When it comes to oil tank installation, choosing the right size and type is crucial for efficient fuel consumption and complying with local regulations. This section will provide an overview of oil tank sizes and types, including tank diameter and length, and above-ground and buried tanks.

Tank Diameter and Length

Oil tanks come in a variety of sizes, typically measured in gallons. The most common sizes for residential use are 275 and 330 gallons, while commercial tanks can range from 500 to 20,000 gallons or more. Choosing the right size tank depends on factors such as property size, fuel consumption, and local regulations.

Tank diameter and length are also important considerations. The diameter of a tank can range from 27 to 44 inches, while the length can range from 44 to 72 inches. The table below shows the calculated volume in cubic inches for different tank sizes:

| Tank Size (Gallons) | Tank Width (Inches) | Tank Height (Inches) | Calculated Volume (Cubic Inches) |

|---|---|---|---|

| 275 | 27 | 44 | 172,375 |

| 330 | 27 | 60 | 235,170 |

| 500 | 37 | 48 | 424,440 |

Above-Ground and Buried Tanks

Oil tanks can be installed above-ground or buried underground. Above-ground tanks are typically less expensive and easier to install, but they take up more space and can be an eyesore. Buried tanks, on the other hand, are more expensive and require excavation, but they are hidden from view and can be a good option for properties with limited space.

Above-ground tanks can be single-wall or double-wall, with double-wall tanks being more expensive but providing an extra layer of protection against leaks. Buried tanks are typically double-wall and require a protective coating to prevent corrosion.

Choosing the right oil tank size and type is essential for efficient fuel consumption and complying with local regulations. Tank diameter and length, as well as above-ground or buried installation, should be carefully considered before making a decision.

Installation Process

Location Selection

Before starting the installation process, the location for the oil tank must be selected. It is recommended to install the oil tank in a location that is easily accessible for maintenance and delivery. The location should also be at least 5 feet away from any property line and 2 feet away from any heating equipment.

If the oil tank is being installed in a garage, it must be located at least 10 feet away from any vehicle and should have proper ventilation. It is also important to ensure that the location allows for proper drainage and is not in an area that is prone to flooding.

Installation by Professionals

Oil tank installations should be done by a team of professionals who are experienced and knowledgeable in the installation process. The team should consist of workers who are licensed and insured.

During the installation process, the old oil tank must be properly removed and disposed of. The new oil tank should be installed according to the manufacturer’s instructions and local regulations. A licensed professional should be able to provide guidance on local regulations and permits that may be required for the installation process.

It is important to ensure that the installation process is done correctly to avoid any safety hazards or leaks. The installation team should conduct a thorough inspection of the tank and connections before filling the tank with oil. Get a free quote on Oil Tank Installation Long Island.

Cost of Oil Tank Installation

When it comes to oil tank installation, the cost can vary depending on several factors. In this section, we will discuss the price factors that affect the cost of installation, as well as scheduling and delivery considerations.

Price Factors

The cost of oil tank installation can vary depending on the size of the tank, the type of tank, and the location of the installation. For example, an above-ground tank may be less expensive to install than an underground tank due to the excavation required. Additionally, the cost of installation may be affected by the need for additional equipment, such as a crane or a pump truck, to move the tank into place.

Another factor that can affect the cost of installation is the need for removal of an existing tank. Removal costs can add to the overall cost of installation, but it is important to properly dispose of an old tank to ensure safety and compliance with local regulations.

Scheduling and Delivery

Scheduling and delivery are important considerations when it comes to oil tank installation. It is important to schedule installation in advance to ensure availability of a qualified installer and to allow time for any necessary permits or inspections. Additionally, it is important to consider the delivery driver’s access to the installation site, as well as any obstacles that may need to be removed to allow for safe and efficient delivery.

It is important to work with a qualified tank installer to determine the most cost-effective and safe installation option for your specific needs.

Oil Tank Connections and Components

When it comes to oil tank installation, it is important to properly connect all necessary components to ensure the safe and efficient operation of the system. The main components that need to be connected include the fill and vent pipes, as well as the supply lines and connections.

Fill and Vent Pipes

The fill and vent pipes are essential components of the oil tank system. The fill pipe is used to add oil to the tank, while the vent pipe allows air to escape as the tank is being filled. It is important to ensure that these pipes are properly installed and maintained to prevent leaks and spills.

To prevent overfilling, most oil tanks are equipped with an oil gauge and a vent alarm. The oil gauge indicates how much oil is in the tank, while the vent alarm sounds an alert when the tank is almost full. It is also important to regularly inspect the fill and vent pipes for any signs of damage or wear.

Supply Lines and Connections

The supply lines and connections are responsible for delivering oil from the tank to the heating system. These components include the oil line, fuel filters, and any necessary fittings and valves.

Proper routing of the oil lines is crucial to prevent leaks and ensure efficient operation. It is also important to regularly inspect the supply lines and connections for any signs of wear or damage, and to replace any faulty components as soon as possible.

The oil tank pressure should also be monitored to ensure that it remains within safe operating limits. This can be done using a pressure gauge or a pressure relief valve. Additionally, all tank plugs should be properly installed and tightened to prevent leaks.

Regulations and Permits

Applicable Codes

Oil tank installation is subject to various regulations and codes. One of the most important codes is NFPA 31, Standard for the Installation of Oil-Burning Equipment. This code specifies the minimum requirements for the installation of above ground oil storage tanks. It covers tank location, tank size, foundation requirements, venting, fill and withdrawal piping, and other important details. It is important to note that some local codes may have additional requirements beyond what is specified in NFPA 31.

Permit Requirements

Oil tank installation doesn’t typically require a permit from the local building department if you’re replacing an existing tank. The permit process ensures that the installation meets all applicable codes and regulations. The permit application typically requires information such as the size and location of the tank, the type of tank, and the installer’s information. The permit fee varies depending on the jurisdiction, but it is usually a nominal amount.

Oil tank installation is subject to various regulations and codes. NFPA 31 is the minimum standard for the installation of oil-burning equipment. Local codes may have additional requirements.

Safety and Maintenance

When it comes to oil tank installation, safety and maintenance are essential to ensure the longevity and efficiency of the tank. Regular inspections and maintenance can help prevent leaks and corrosion, as well as ensure that the tank is functioning properly.

Leak Prevention and Management

One of the most important aspects of oil tank maintenance is leak prevention and management. Regular inspections are vital to ensure that there are no visible signs of leaks or damage to the tank. If a leak is detected, it should be addressed promptly to prevent further damage and potential environmental hazards.

It is also important to have a shutoff valve installed on the tank to prevent oil from leaking out in the event of a malfunction or accident. Additionally, oil sludge disposal and abandonment regulations should be followed to ensure that the tank is properly disposed of when it is no longer in use.

Corrosion and Rust Management

Corrosion and rust are common issues that can affect both the internal and external components of an oil tank. Internal corrosion can be caused by condensation, while external corrosion can be caused by exposure to the elements.

To prevent corrosion and rust, it is important to keep the tank clean and free of debris. Regular cleaning can help remove any buildup that may contribute to corrosion. Additionally, protective coatings can be applied to the tank to prevent rust and corrosion from forming.

Popular Oil Tank Brands

When it comes to oil tank installation, choosing the right brand is crucial. There are many brands on the market, but two of the most popular are Granby Oil Tanks and Roth Tanks. Get a free quote on Oil Tank Installation Long Island.

Granby Oil Tanks

Granby Oil Tanks is a well-established brand that has been in the industry for over 60 years. They offer a wide range of oil tanks to suit different needs, including residential and commercial tanks. The tanks are made of high-quality materials, such as steel and fiberglass, and come with a range of features to ensure safety and durability.

One of the key benefits of Granby Oil Tanks is their warranty. They offer a 10-year warranty on their tanks, which is one of the longest in the industry. This gives customers peace of mind that their tank is built to last.

Roth Tanks

Roth Tanks is another popular brand in the oil tank industry. They are known for their innovative double-wall construction, which provides an extra layer of protection against leaks and spills. The tanks are made of a high-density polyethylene material, which is resistant to corrosion and impact.

One of the key benefits of Roth Tanks is their compact size. They are designed to fit into tight spaces, making them ideal for small homes or businesses. They also offer a 30-year warranty, which is one of the longest in the industry.

Frequently Asked Questions

What is the cost of a 275 gallon outdoor oil tank?

The cost of a 275-gallon outdoor oil tank can vary depending on the brand and the location. On average, the cost ranges from $2,700 and up (installed price).

How much does it cost to replace a basement oil tank?

The cost to replace a basement oil tank varies depending on the size of the tank and the type of installation. On average, the cost ranges from $2,900 and up (installed price).

What is the price of a 250 gallon oil tank?

The price of a 250-gallon oil tank can vary depending on the brand and the location. On average, the cost ranges from $2,700 and up.

Can I install an oil tank on my own?

It is not recommended to install an oil tank on your own. Installation should be done by a licensed professional to ensure safety and compliance with local regulations.

What are the installation requirements for an oil tank?

Oil tanks must be installed on a level, stable surface and should be placed at least 5 feet away from any combustible material. The installation should also comply with local regulations and codes.

What is the recommended height for an oil tank off the ground?

The recommended height for an oil tank off the ground is 18 inches. This allows for proper ventilation and access for maintenance.